Home

Contact

Information

sales@raysdiesandtubing.com

telephone: (802)

868-2040

fax: (802) 868-2181

mailing address:

Ray's Dies & Tubing

P.O. Box 385

St. Albans, VT 05478

shipping address:

Ray's Dies & Tubing

718 Route 78

Swanton, VT 05488

copyright 2017 Ray's Dies &

Tubing

All Rights Reserved.

Web Site Design by Jim Gadue

Photography by Richard

Gadue

|

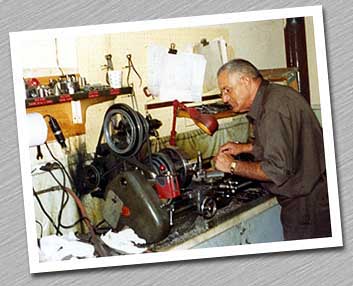

From 1960 to 1976 Ray's

Extruder Die Service operated out of a converted garage

at Seven Walnut Street in St. Albans, Vermont. From

within these humble surroundings Raymond Gadue produced a

product of such quality that companies from around the

country and around the world sought him out. His work

even went to the moon on at least one Apollo mission. We

at Ray's Extrusion Die Service take pride in these humble

beginnings and strive to live up to the standards of

quality and service set by our founder. From 1960 to 1976 Ray's

Extruder Die Service operated out of a converted garage

at Seven Walnut Street in St. Albans, Vermont. From

within these humble surroundings Raymond Gadue produced a

product of such quality that companies from around the

country and around the world sought him out. His work

even went to the moon on at least one Apollo mission. We

at Ray's Extrusion Die Service take pride in these humble

beginnings and strive to live up to the standards of

quality and service set by our founder.

Raymond Gadue was

a dreamer, a handyman and a believer in making it big.

His attempts at greatness included the manufacture of

soap as a special hand cleaner, a potato chip company,

ownership of a small country store, and he even tried his

hand at selling typewriters. Ray trained as a machinist

while working for a large corporation in Pittsfield,

Massachusetts, and worked with his son, Ray Jr., doing

building construction, to name just a few of his

enterprises. Raymond Gadue was

a dreamer, a handyman and a believer in making it big.

His attempts at greatness included the manufacture of

soap as a special hand cleaner, a potato chip company,

ownership of a small country store, and he even tried his

hand at selling typewriters. Ray trained as a machinist

while working for a large corporation in Pittsfield,

Massachusetts, and worked with his son, Ray Jr., doing

building construction, to name just a few of his

enterprises.

It was this

construction work that found him by a wire coating

factory being built in Vermont that he and his son were

working on. When the building was complete both Rays went

to work for the company. It was this

construction work that found him by a wire coating

factory being built in Vermont that he and his son were

working on. When the building was complete both Rays went

to work for the company.

Ray watched from a distance

as an engineer representing a manufacturer of a wire

coating machine was having problems getting it to operate

effectively. Ray watched from a distance

as an engineer representing a manufacturer of a wire

coating machine was having problems getting it to operate

effectively.

"What's the

problem?" Ray queried. "What's the

problem?" Ray queried.

"It's the die

insert. If we can find one good one out of ten we're

lucky," the engineer shot back. They were

experiencing short runs, the insulated coatings were

tearing, and burn outs were frequent. "It's the die

insert. If we can find one good one out of ten we're

lucky," the engineer shot back. They were

experiencing short runs, the insulated coatings were

tearing, and burn outs were frequent.

"If a man

could design a *TFE die that would work, he would have it

made." "If a man

could design a *TFE die that would work, he would have it

made."

This thought

echoed through Ray's mind. "One that would

work?" This thought

echoed through Ray's mind. "One that would

work?"

Ray was soon to

have plenty of time to think about it, for the new and

struggling plant was forced into layoffs, and the man

with so many dreams was unemployed. The year was 1960 and

unemployment checks amounted to $35.00 per week. The

design of a proper *TFE die would be the answer to having

it made. He thought of this and knew that it must be made

of a high quality non-corrosive steel. He found such a

steel in the shaft of an old outboard motor that was bent

and seemingly useless except for a prybar. Ray purchased

it for $5.00 at a time that $5.00 would buy a lot of

groceries. He then proceeded to rent a lathe at a dollar

an hour. No one really remembers how long it took him to

make his first die, but Ray knew in his heart that the

inspiration that he had felt would lead him to a finished

product that would work. Ray was soon to

have plenty of time to think about it, for the new and

struggling plant was forced into layoffs, and the man

with so many dreams was unemployed. The year was 1960 and

unemployment checks amounted to $35.00 per week. The

design of a proper *TFE die would be the answer to having

it made. He thought of this and knew that it must be made

of a high quality non-corrosive steel. He found such a

steel in the shaft of an old outboard motor that was bent

and seemingly useless except for a prybar. Ray purchased

it for $5.00 at a time that $5.00 would buy a lot of

groceries. He then proceeded to rent a lathe at a dollar

an hour. No one really remembers how long it took him to

make his first die, but Ray knew in his heart that the

inspiration that he had felt would lead him to a finished

product that would work.

He excitedly sent

his die to a local Vermont wire coating plant to try.

After a period of a few weeks, the company ordered ten

more. Still no invoice was sent, and finally a call came

for Ray to go to their office. The questions started

rolling out at Ray. He excitedly sent

his die to a local Vermont wire coating plant to try.

After a period of a few weeks, the company ordered ten

more. Still no invoice was sent, and finally a call came

for Ray to go to their office. The questions started

rolling out at Ray.

"How much are

you charging us?" "How much are

you charging us?"

In old Vermont

fashion, Ray asked back, "Do they work?" In old Vermont

fashion, Ray asked back, "Do they work?"

The engineer

replied back, "so-so." The engineer

replied back, "so-so."

Ray quoted the

price. Ray quoted the

price.

"If we order

a hundred, would you give us a discount?" "If we order

a hundred, would you give us a discount?"

His confidence now

bursting, for Ray knew they wouldn't be asking for a

hundred if they didn't like the product, answered,

"No, they are all milled by hand, and it takes me as

long to mill the last one as it does the first." Ray

got the order at his price. His confidence now

bursting, for Ray knew they wouldn't be asking for a

hundred if they didn't like the product, answered,

"No, they are all milled by hand, and it takes me as

long to mill the last one as it does the first." Ray

got the order at his price.

E. I. Dupont, a company

always searching for dies that compliment their *TFE

coatings called Ray and wanted to know how big he was.

Ray jokingly gave them his weight, then told them he was

one man working out of his garage. Their words were that

he would "Grow with the industry." E. I. Dupont, a company

always searching for dies that compliment their *TFE

coatings called Ray and wanted to know how big he was.

Ray jokingly gave them his weight, then told them he was

one man working out of his garage. Their words were that

he would "Grow with the industry."

Ray's Extruder

Dies are now being used all over the world. They were right. Ray

grew with the industry. He achieved his realization of a

worthy goal. He established a business that is, to this

day, carried on in a manner of quality not affected by

the pressures of competition. Ray's Extruder

Dies are now being used all over the world. They were right. Ray

grew with the industry. He achieved his realization of a

worthy goal. He established a business that is, to this

day, carried on in a manner of quality not affected by

the pressures of competition.

Ray Sr. Passed on

in 1977, but not before he had it made. Having it made to

Ray meant being able to travel and see this beautiful

country. He did this with his loving wife, Gertrude, who

stood by him through his various projects. Ray Sr. Passed on

in 1977, but not before he had it made. Having it made to

Ray meant being able to travel and see this beautiful

country. He did this with his loving wife, Gertrude, who

stood by him through his various projects.

Ray Jr., who now heads our company,

shares his Dad's Vermont ingenuity and inventive

interest. They worked together as a team beginning in

1965 when it was Ray Jr.'s job to make the wire guide

tips that were used in the dies. Ray Jr., who now heads our company,

shares his Dad's Vermont ingenuity and inventive

interest. They worked together as a team beginning in

1965 when it was Ray Jr.'s job to make the wire guide

tips that were used in the dies.

When

Ray Sr. Died in 1977, Ray found himself alone, as his

brother, who worked alone with him and his Dad for

awhile, decided to follow his career with a large

corporation. Ray knew that he must expand, and with the

help of his wife, Eileen, they began a program of

controlled growth. They were determined not to forsake

quality for expansion. When

Ray Sr. Died in 1977, Ray found himself alone, as his

brother, who worked alone with him and his Dad for

awhile, decided to follow his career with a large

corporation. Ray knew that he must expand, and with the

help of his wife, Eileen, they began a program of

controlled growth. They were determined not to forsake

quality for expansion.

The

first opportunity came when a friend told him of a

company that was going out of business and they had a

grinder for sale. The price was $1,500, and it was the

only time that they borrowed money for expansion. Eileen

remembers paying $63 per month on a machine that sat in

storage for two years. Ray admits that when he bought it

he didn’t know what its uses were but couldn’t

pass up the deal. Today the same grinder cost over

$30,000. The

first opportunity came when a friend told him of a

company that was going out of business and they had a

grinder for sale. The price was $1,500, and it was the

only time that they borrowed money for expansion. Eileen

remembers paying $63 per month on a machine that sat in

storage for two years. Ray admits that when he bought it

he didn’t know what its uses were but couldn’t

pass up the deal. Today the same grinder cost over

$30,000.

Ray

Jr., like his father, set out to master the machine, and

it wasn’t long before Ray’s Extrusion Dies

& Tubing became as well know for their pioneering in

centerless grinding of the most intricate tubing as for

their dies. For example, Ray has ground tubing that is

used by doctors in exploratory procedures to diagnose

heart problems. Since it is introduced into artery and

threaded through into the heart, the diameter must be

small and the OD. finish ultra smooth, Ray’s

comments on this were, "We had to violate a few

commonly accepted rules of procedure for conventional

work" Ray

Jr., like his father, set out to master the machine, and

it wasn’t long before Ray’s Extrusion Dies

& Tubing became as well know for their pioneering in

centerless grinding of the most intricate tubing as for

their dies. For example, Ray has ground tubing that is

used by doctors in exploratory procedures to diagnose

heart problems. Since it is introduced into artery and

threaded through into the heart, the diameter must be

small and the OD. finish ultra smooth, Ray’s

comments on this were, "We had to violate a few

commonly accepted rules of procedure for conventional

work"

Ray

believes the stainless steel tubing market has been a

tremendous boost to their expansion because they offer

specialized cutting and sizing. To develop this part of

their business Ray spent years of searching for a quality

manufacturer where he could purchase his volume

requirements to satisfy the needs of his customers.

Although Ray believes in making a profit, his method of

purchasing saves his clients money because, in the small

business tradition, he passes the saving on. Most of the

customers actually prefer to have their orders precision

cut and shaped rather than utilizing their own machine

shop. Ray

believes the stainless steel tubing market has been a

tremendous boost to their expansion because they offer

specialized cutting and sizing. To develop this part of

their business Ray spent years of searching for a quality

manufacturer where he could purchase his volume

requirements to satisfy the needs of his customers.

Although Ray believes in making a profit, his method of

purchasing saves his clients money because, in the small

business tradition, he passes the saving on. Most of the

customers actually prefer to have their orders precision

cut and shaped rather than utilizing their own machine

shop.

print concepts prada square glasses instagram spam followers gucci butik mutual followers instagram teams chatgpt outlet belt followers instagram tracker prada online stores prada sport boots instagram 3000 followers prada sport boots gorras prada mujer prada optical biggest instagram followers the gift aselin debison yachting hat instagram followers 20k red prada boots gucci black friday sale 2016 prada crystal skirt prada sunglasses mens prada kiss prada logo slides prada tasche chatgpt programming prada vogue tommy hilfiger outlet online store prada shoes leather prada pr17 siding proposal sample prada lug boots prada candy sephora chatgpt 日本語 cuisinart outlet canada goose outlet store academie da vinci fabric for cork board prada online stores prada mask is chatgpt detectable compra followers instagram prada downtown chatgpt competitor prada 08ys sunglasses birkenstock outlet store captain shirt with epaulets extra large cork board prada leather slides chatgpt podcast prada sweatsuit mens prada sunglasse new instagram followers doug dunham prada glasses white custom captain hats twicsy instagram followers mosaic tampa fl chatgpt چیست prada loafer platform chatgpt turnitin prada cleo white chatgpt coin burlap colors chatgpt io prada crossbody wallet emilio pucci outlet prada green glasses prada bag cost captain hats for sale prada fuzzy bag chatgpt nvidia tienda tommy cerca de mí prada boston bag fake beard makeup prada tumbler pie jesus meaning prada pumps sale prada loafers styled chatgpt coin yokohoma prada prada gloves mens crazy horse steak house saloon app chatgpt prada brixxen boots prada cleo crystal silicone head instagram followers ads prada boutiques rob schneider orgasm guy prada hexagon sunglasses pasupplierportal meundies t shirt kon tiki makeup instagram block followers manatee high school focus aeropostale factory rosemont brunch how to make a fake mustache stick electric mashman helmet prada sunglasse make wigs prada internship how do i get aaa travel books rihanna instagram followers plus followers instagram zadig & voltaire outlet bing vs chatgpt chatgpt 日本語 gucxi iko nordic sneakers prada

The

story is really the same today of ingenuity, quality, and

confidence of a small Vermont based company serving a

very large industry. Ray’s Extrusion Dies &

Tubing is still family owned and operated, where values

have been handed down from generation to generation. The

story is really the same today of ingenuity, quality, and

confidence of a small Vermont based company serving a

very large industry. Ray’s Extrusion Dies &

Tubing is still family owned and operated, where values

have been handed down from generation to generation.

* A Trademark of E.I.

Dupont Co.

|